|

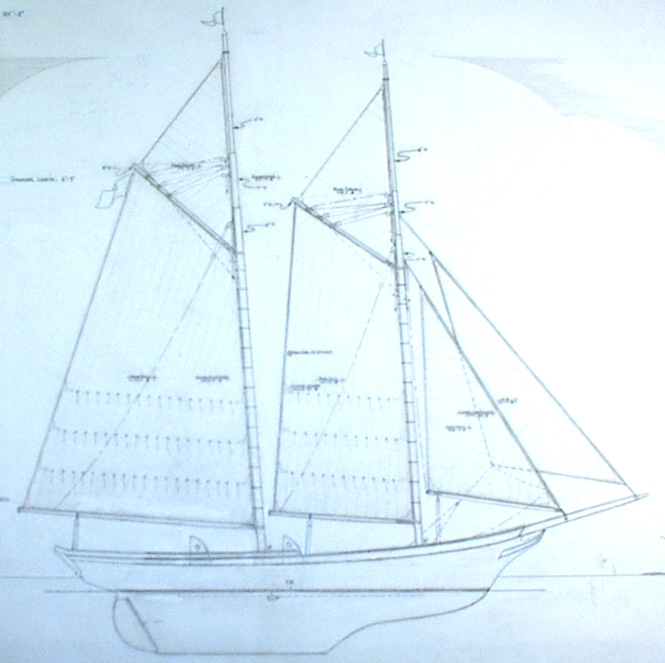

| The partially completed profile and rig for the Halie & Matthew 90 |

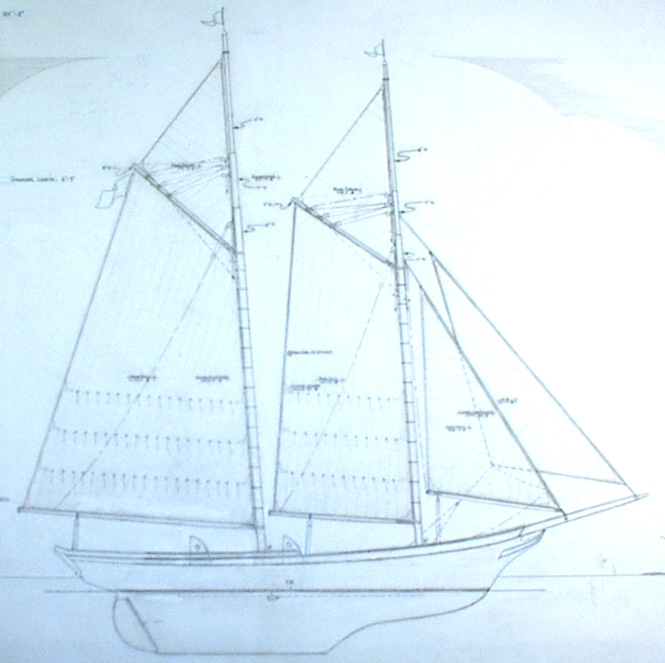

90' Clipper Bowed Gaff Rigged Schooner

for

Passenger Carrying in Downeast Maine

03/28/2002

|

| The partially completed profile and rig for the Halie & Matthew 90 |

Accommodations

The schooner has 10 staterooms with en suite heads with showers. Each staterom has a

double berth plus provision for a pipe or root berth for one above it. The saloon is aft

of the mainmast and has a large skylight on an 18" high trunk above it. Aft of this

is the galley and crew's quarters, including a private double stateroom for the Cook and a

large stateroom with a double berth and two singles for the Captain and his family. This

also requires a low trunk. Otherwise the vessel is to be essentially flush decked. We will

try to accommodate up to 90 day passengers as well.

Rig

Rig is to be that of a double topsail gaff schooner on the pattern of the later

fishing schooners such as the Fredonia type. Steel masts are contemplated.

Some spars may conveniently be solid wood, hollow wood or aluminum. We would attempt to

judge this on the individual case and the building situation and crew capabilities. For

instance booms might profitably be solid wood as the weight is helpful in proper sail set.

Conversely the gaffs should be as light as possible to minimize sag off to leeward and the

resulting sail twist.

Lines

The lines are appropriate to the rig but modified from the traditional to give a

lighter less expensive vessel to build as is appropriate to the light "cargo".

The designer would prefer using outside lead ballast to make certification easier. This in

the form of cast lead pieces of the largest size that can be transported and maneuvered

into position. These have the advantage that they might be added after the rest of the

hull was built and transported near the water to keep the height low and weight down to an

amount transportable by a single large hydraulic trailer. Also the lead would protect the

structure of the boat from abrasion in hauling or grounding. However, the clients favor

inside ballast of lead resin. This is acceptable but to get the same degree of stability

has required careful attention to keel shape and structure. Great emphasis has been placed

on developing lines that would both be easy to get certified and seaworthy enough for

offshore use. Also a great deal of effort has gone into making sure the lines have the

best possible bias toward a very fast vessel as fast is always fun for the passengers and

makes it easier to get the best crew. At the time of this writing the lines are complete

and we are extremely pleased with them. w

Engines & Equipment

There was a good deal of discussion about whether to use a single diesel engine or two

for propulsion. Either was perfectly acceptable to the designer. Eventually this was

decided in favor of a single engine with a centerline shaft in a propeller aperture. The

designer recommends the Lunenburg schooner windlasses of appropriate size arranged to be

operated either manually or by hydraulics. In the galley we recommend the Dickinson

"Beaufort" diesel stove for cooking. In the heads we recommend the Raritan

"ElectraSan" sewage treatment systems for each pair of heads. This would

normally be combine with a holding tank for retention in the event that the vessel must

travel through a no-discharge area at some time in the future. For the actual water closet

we recommend the Raritan PHE II if you wish a head with electric flush capabilities but

wish to retain the manual pumping capability. For a more economical fully manual flush

system we recommend the Baby Blake heads.

Construction

Sheathed strip construction was recommended by the designer in light of the need for

this vessel to be easily built one off with the minimum wasted expense and labor and also

the minimum overall material and labor cost generally. Additionally sheathed strip

construction keeps the routine maintenance and repair expenses down as much as possible

which is a very important factor in profitability. However, the clients prefer

conventional solid fiberglass construction fully framed with glass hat section frames so

that is what we have gone with. All bulkheads will be structural. While this may be

somewhat more expensive in materials and requires more labor and therefore more expense

there is little doubt that it will produce a good solid vessel.

We will keep you posted on progress on this design as we can.