|

This is a great advance for small yacht design

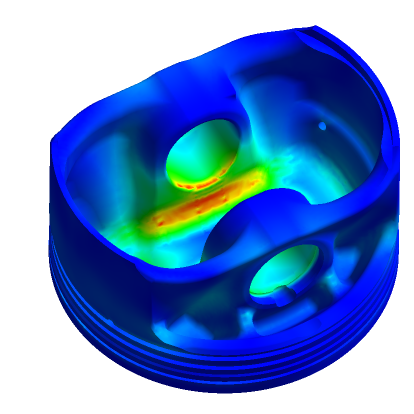

firms. Finite Element Analysis or FEA allows us to apply

stresses to an object and observe where stress concentrates, the

type and amount of deformation under a given set of loads, whether

the part is likely to fail, or fatigue under the predicted loads,

what the failure level and type of failure at that level is likely

to be. This can be extraordinarily useful as a check on the ordinary "cook book" engineering formulas. The formulas that we find in books to model stress, and strain or deformation, are excellent and should never be neglected. However finite element analysis by performing a great many calculations on very small areas of a given part and applying the results to neighboring areas allows finding areas where stress may concentrate causing undue strain, deformation, and failure or cumulative fatigue. Therefore you may catch problems with the design of a critical fitting that you could not otherwise foresee. Viewed another way, in applying the normal formulas of structural analysis, we may knowingly accept that we may need to use a heavier section to account for our inability to define the stresses any more precisely with the given formulas. In this case careful use of Finite Element Analysis may reveal areas in which significant weight can be saved without any compromise in strength. In fact in some cases a reduction in weight may be tailored to reduce stress concentration and result in a lighter part that is actually stronger. Now in yacht design a lot of the major structures such as the hull and deck are likely to be made of materials that are not equally strong in all directions and which will be defined largely by scantlings rules. Nevertheless a lot of details of these structures and a great many fittings, mechanical devices, and rigging parts can benefit greatly by using Scan&Solve. A common example is that a carefully analyzed masthead fitting may be quite a bit lighter than one which hasn't had the benefit of cross checking the initial design with FEA. Because of the great distance above the rest of the boat even quite modest savings in weight aloft may produce quite significant increases in stability and therefore performance. In some technical fields, where weight is immensely critical and the resulting structures are extremely expensive, Finite Element Analysis may be cost effective at the higher prices we have seen in the past. However the average yacht design firm cannot justify the huge costs of the Finite Element Analysis packages of the past. Just as Rhino finally tipped the balance and threw all design firms rapidly into using CAD, Scan&Solve is doing the same for FEA. The specific conceptual advances which have made creating an FEA plug-in at a low price need not be detailed here, but they have brought the price of FEA down to the point where now it is cost effective for even the smallest firm. I expect that we will soon see Scan&Solver regarded as an essential tool of yacht design. Few design firms will be able to justify being without it. (tm) Yacht Design School / Publishing / Home / YDS Enrollment Form |